About Jehel’s

Infrastructure and R&D

and Reliable Solutions

Infrastructure Facility at JEHEL

Inhouse design team technological with excellence in Mechanical, Electrical and Hydraulic design.

1 lac sq. ft covered shop floor equipped with all modern manufacturing facilities.

R&D team with modern 3D analysis softwares for VA/VE

International Quality cylinders manufacturing

Comprehensive quality assurance approach confirming to international standards.

Providing high quality technical products at an economical cost

Experienced service team of 25 members catering India & abroad

State-of-the-Art Production Facilities

Jehel boasts cutting-edge manufacturing facilities equipped with the latest technology and machinery for precision engineering and production of hydraulic equipment.

Customization Capabilities

With our versatile infrastructure, Jehel offers extensive customization capabilities to tailor hydraulic solutions to the unique requirements of our clients.

Comprehensive Testing Facilities

Jehel’s infrastructure includes comprehensive testing facilities where our hydraulic equipment undergoes rigorous quality control and performance testing.

Research & Development

At JEHEL

Our design department is on a constant endeavour to upgrade the products with latest technology and innovative idea so as to meet our clients’ diverse and ever changing requirements. We have latest R&D technology and softwares inhouse with which we can develop anything our customers require.

Hydraulic Truck Unloader : With Drive through technology

This is a tipical arrangement of truck unloading where the reversal of the truck is eliminated as the truck move ower the hopper/BRU through a Drive over Door and positioned over the tilting platformn which tilts and unload the material and the truck mooved out to the same direction.

Snow plough attachment

We are the first one to develop snow plough attachment for BRO (Ministry of Defence). This machine is efficient to remove snow from hilly roads and make the roads available to use.

Remote controlled AFR handler

We are the first company in India to develop Radio-remote controlled hydraulically operated Alternate fuel handling m

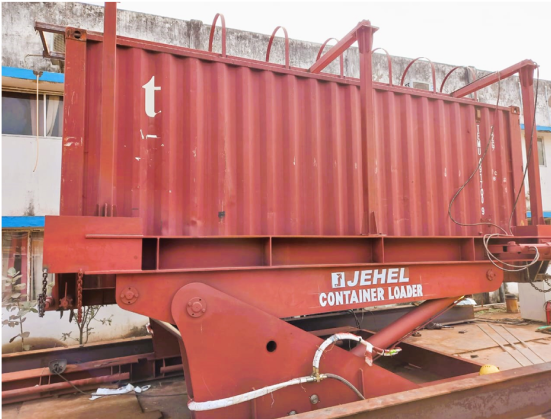

Container Tilter

The Hydraulically operated container loader is suitable to handle 20feet containers directly from the truck. Manual locking at 8 points to ensure secured container holding. A pair of heavy duty lift cylinders capable to lift the container up to 87º with filling door opening hydraulic mechanism. u Measured and automated filling of the material into the container.