Introduction

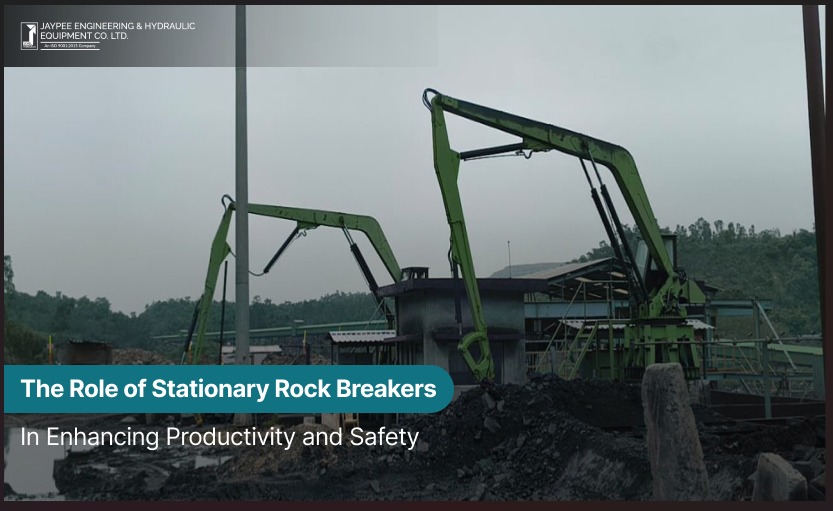

In the realms of construction and mining, rock breaking is a critical operation that can significantly impact project timelines and safety. As industries strive for greater efficiency and safety, the role of stationary rock breakers becomes increasingly vital. These powerful machines not only enhance productivity but also ensure a safer working environment for all involved.

What are Stationary Rock Breakers?

Definition and Functionality

Stationary rock breakers are heavy-duty machines designed to break down large volumes of rock into smaller, manageable pieces. Unlike their mobile counterparts, these machines are fixed in one place, often located at quarries or construction sites, providing a consistent and reliable solution for rock breaking needs.

Different Types of Stationary Rock Breakers

There are various types of stationary rock breakers, including hydraulic breakers, pneumatic breakers, and electric breakers. Each type serves specific functions and is tailored to different rock types and project requirements.

How Stationary Rock Breakers Work

Mechanism of Operation

Stationary rock breakers typically utilize hydraulic power to deliver forceful blows to the rock surface. The mechanism involves a hydraulic cylinder that compresses and extends, driving a hammer or chisel into the rock. This impact fractures the rock, making it easier to transport or process.

Key Components of Rock Breakers

Key components of stationary rock breakers include the hydraulic system, the breaker arm, the hammer, and the control system. Understanding how these parts work together helps in appreciating the machine’s effectiveness and efficiency in breaking rock.

Benefits of Using Stationary Rock Breakers

Increased Productivity

One of the most significant advantages of using stationary rock breakers is the boost in productivity. These machines can operate continuously, breaking down rock faster than manual methods, which can lead to shorter project timelines and increased output.

Enhanced Precision in Breaking Rock

Stationary rock breakers offer enhanced precision, allowing operators to target specific areas without damaging surrounding materials. This precision reduces waste and ensures that only the necessary rock is broken down.

Reduction of Operational Costs

With their ability to operate efficiently, stationary rock breakers can reduce operational costs. Less labor is required for rock breaking tasks, and the speed of work can lead to savings in equipment rental and maintenance costs.

Safety Enhancements with Stationary Rock Breakers

Minimizing Risks to Workers

The use of stationary rock breakers minimizes risks to workers by reducing the need for manual rock breaking, which is often hazardous. Operators can control the machines from a safe distance, enhancing overall site safety.

Reducing Noise and Vibration Levels

Stationary rock breakers are designed to operate with lower noise and vibration levels compared to traditional breaking methods. This reduction is beneficial not only for worker safety but also for the surrounding environment.

Decreasing the Chance of Fly Rock

Fly rock, or debris that is propelled during breaking operations, poses a significant safety hazard. Stationary rock breakers minimize this risk by precisely targeting rock with controlled impacts, thus reducing the chance of flying debris.

Applications of Stationary Rock Breakers

Use in Quarrying

In quarrying operations, stationary rock breakers are essential for breaking large boulders and preparing materials for further processing. Their efficiency contributes to a steady supply of crushed rock for construction projects.

Role in Mining Operations

In mining, these machines are used to break down ore and rock, facilitating easier extraction. This application is crucial in maximizing the yield from mining operations while ensuring safety standards are upheld.

Application in Demolition Projects

Stationary rock breakers also find applications in demolition projects, where they help dismantle structures safely and efficiently. Their precision allows for controlled demolition without compromising the surrounding area.

Choosing the Right Stationary Rock Breaker

Factors to Consider (Size, Power, and Application)

When selecting a stationary rock breaker, it’s essential to consider factors such as size, power, and the specific application. Matching the right machine to the job requirements ensures optimal performance and safety.

Matching the Breaker to Project Needs

Different projects may require different types of breakers. Understanding the characteristics of the rock being worked on and the project scope will help in choosing the most effective equipment.

Maintenance of Stationary Rock Breakers

Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the longevity and performance of stationary rock breakers. Routine checks help identify potential issues before they become significant problems, minimizing downtime and repair costs.

Common Maintenance Practices

Common maintenance practices include inspecting hydraulic systems, checking for wear on breaker arms and hammers, and ensuring all safety features are operational. A well-maintained machine not only operates efficiently but also enhances safety on site.

Technological Advances in Rock Breaking

Innovations in Stationary Rock Breaker Design

Recent advancements in technology have led to the development of more efficient and powerful stationary rock breakers. Features such as automated controls and enhanced hydraulic systems improve performance and ease of use.

The Role of Automation and Remote Control

The integration of automation and remote control technology is transforming how stationary rock breakers are operated. This innovation allows for more precise control and monitoring, further enhancing safety and productivity.

Real-World Experiences with Stationary Rock Breakers

Success in Quarrying Operations

In a recent quarrying operation, the introduction of stationary rock breakers led to a 30% increase in productivity. The operators noted a significant reduction in noise and vibration, contributing to a safer working environment and improved morale among the team.

Enhanced Safety in Mining Projects

A mining company integrated stationary rock breakers into their workflow, which resulted in reduced extraction time by 40%. This efficiency not only improved the overall yield but also created a safer working environment as workers could operate from a distance, minimizing their exposure to hazardous conditions.

Future Trends in Rock Breaking Technology

Emerging Technologies and Their Impact

Emerging technologies, such as AI and machine learning, are expected to revolutionize rock breaking. These advancements will enhance efficiency and precision, allowing for even safer and more productive operations.

Sustainability Considerations

As industries move towards more sustainable practices, the development of eco-friendly rock breaking technologies will play a crucial role. Energy-efficient machines and methods will help reduce the environmental impact of mining and construction activities.

Conclusion

Stationary rock breakers are essential tools that significantly enhance productivity and safety in the construction and mining industries. By understanding their role, benefits, and applications, companies can make informed decisions that lead to more efficient operations. As technology continues to evolve, these machines will undoubtedly play an even more critical role in shaping the future of rock breaking. Embracing these innovations will ensure that safety and efficiency remain at the forefront of industry practices, paving the way for a safer, more productive working environment.