Introduction

The forestry and timber industries play a crucial role in the global economy, providing materials essential for construction, furniture, and paper products. However, these industries also face significant challenges, including the need for efficiency, safety, and sustainability. In this context, mobile log grabbers emerge as invaluable tools that enhance productivity while ensuring safe and responsible operations.

What are Mobile Log Grabbers?

Definition and Functionality

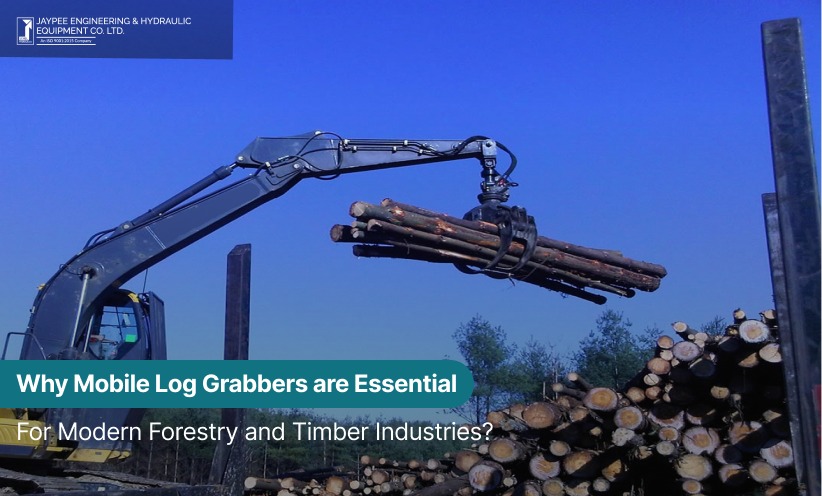

Mobile log grabbers are specialized machinery designed to grasp and lift logs for transportation and processing. These powerful devices can be mounted on various types of equipment, such as trucks or cranes, providing flexibility in log handling. Their primary function is to simplify the movement of logs, making operations smoother and more efficient.

Key Features of Mobile Log Grabbers

These grabbers come equipped with several features that enhance their usability, including hydraulic controls, adjustable gripping arms, and rotating heads. Their design allows operators to handle logs of varying sizes and weights, making them suitable for diverse forestry applications.

Advantages of Using Mobile Log Grabbers

Increased Efficiency in Log Handling

One of the standout benefits of mobile log grabbers is their ability to improve efficiency. These machines can quickly and accurately grasp logs, reducing the time and effort required for manual handling. As a result, logging operations can proceed at a faster pace, leading to increased productivity.

Enhanced Safety for Operators

Safety is paramount in the forestry industry. Mobile log grabbers minimize the risks associated with log handling by allowing operators to work from a safe distance. This reduction in manual lifting decreases the likelihood of injuries, creating a safer working environment for all involved.

Reduced Labor Costs

By streamlining log handling processes, mobile log grabbers can significantly lower labor costs. Fewer workers are needed for manual log movement, allowing companies to allocate resources more efficiently. This cost-effectiveness is particularly beneficial in a competitive industry.

How Mobile Log Grabbers Work

Mechanism of Operation

Mobile log grabbers operate using hydraulic systems that power the gripping mechanism. When activated, these hydraulics allow the grabber to open and close, securely holding logs in place for transportation or processing. The precise control of these movements enhances overall efficiency.

Key Components and Their Functions

Key components of a mobile log grabber include the hydraulic pump, the gripping arms, and the control system. Each part plays a vital role in ensuring the smooth operation of the machine. Understanding these components helps operators maximize the grabber’s capabilities.

Applications in the Forestry Industry

Use in Timber Harvesting

Mobile log grabbers are essential in timber harvesting, allowing for quick and efficient removal of logs from the forest. Their ability to handle logs of various sizes makes them ideal for diverse harvesting operations.

Role in Log Transportation

Once logs are harvested, mobile log grabbers facilitate their transportation to processing facilities. By securely gripping logs, these machines enable safe and efficient movement, reducing the risk of accidents during transport.

Application in Land Clearing

In addition to timber harvesting and transportation, mobile log grabbers are also used in land clearing operations. They help remove fallen trees and debris, making way for new construction or land development projects.

Impact on Timber Processing

Streamlining Log Sorting and Stacking

In timber processing facilities, mobile log grabbers play a crucial role in sorting and stacking logs. Their efficiency reduces the time spent organizing logs, allowing for a more streamlined processing workflow.

Facilitating Faster Processing Times

With mobile log grabbers, processing times can be significantly reduced. The ability to quickly and accurately move logs from one stage of processing to another accelerates overall operations, benefiting manufacturers and suppliers alike.

Environmental Benefits of Mobile Log Grabbers

Minimizing Environmental Impact

Using mobile log grabbers can minimize the environmental impact of logging operations. Their efficiency reduces fuel consumption and emissions compared to traditional methods, promoting a more sustainable approach to forestry.

Promoting Sustainable Forestry Practices

Mobile log grabbers encourage sustainable practices by facilitating selective logging and responsible land management. Their precision helps ensure that only necessary trees are removed, preserving the integrity of the ecosystem.

Choosing the Right Mobile Log Grabber

Factors to Consider (Size, Capacity, and Compatibility)

When selecting a mobile log grabber, it’s essential to consider factors such as size, capacity, and compatibility with existing equipment. Ensuring the right fit for specific applications maximizes efficiency and performance.

Matching the Grabber to Project Needs

Different projects may require different types of grabbers. Understanding the project requirements and the characteristics of the logs being handled will help in choosing the most effective equipment.

Maintenance and Care for Mobile Log Grabbers

Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the longevity and performance of mobile log grabbers. Routine checks help identify potential issues before they become significant problems, minimizing downtime and repair costs.

Common Maintenance Practices

Common maintenance practices include inspecting hydraulic systems, checking for wear on gripping arms, and ensuring all safety features are operational. A well-maintained machine not only operates efficiently but also enhances safety on site.

Technological Advancements in Mobile Log Grabbers

Innovations in Design and Functionality

Recent advancements in technology have led to the development of more efficient and powerful mobile log grabbers. Features such as automated controls and enhanced hydraulic systems improve performance and ease of use.

Integration of Smart Technology

The integration of smart technology into mobile log grabbers is transforming operations. Real-time monitoring systems provide data on performance, allowing operators to make informed decisions and improve efficiency.

Real-World Experiences with Mobile Log Grabbers

Success in Timber Harvesting Projects

In a recent timber harvesting project, the introduction of mobile log grabbers led to a 25% increase in operational efficiency. The team was able to harvest and transport logs much faster than with traditional methods, resulting in significant time and cost savings.

Enhanced Safety in Urban Logging Operations

A construction company utilizing mobile log grabbers for urban logging reported a noticeable decrease in workplace accidents. The ability to control the machinery from a safe distance minimized risks and contributed to a safer working environment.

Future Trends in Forestry Equipment

The Growing Demand for Advanced Machinery

As the demand for timber continues to rise, so does the need for advanced forestry equipment. Mobile log grabbers will likely evolve further to meet the challenges of modern logging operations.

Sustainability Considerations

Future innovations will focus on sustainability, emphasizing energy-efficient designs and eco-friendly materials. This trend will align with the industry’s broader commitment to responsible forestry practices.

Conclusion

Mobile log grabbers are essential tools that significantly enhance productivity and safety in the forestry and timber industries. By understanding their role, benefits, and applications, companies can make informed decisions that lead to more efficient operations. As technology continues to evolve, these machines will undoubtedly play an even more critical role in shaping the future of logging and timber processing. Embracing these innovations will ensure that safety and efficiency remain at the forefront of industry practices, paving the way for a more sustainable and productive future.